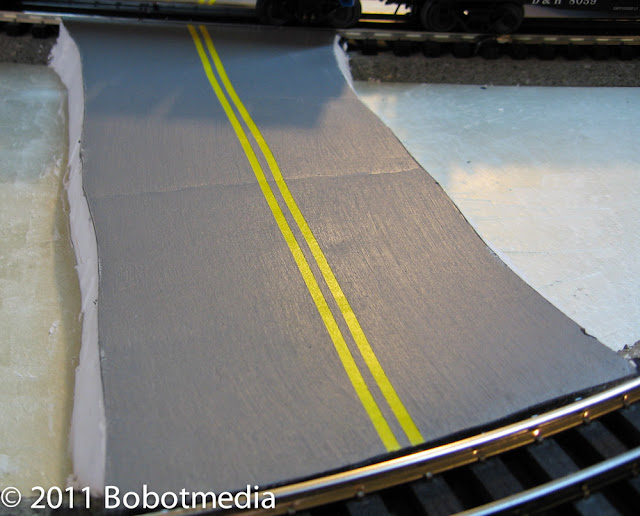

A few photos showing my work in progress for my roads. One road crossing tracks coming into town and another heading out to a more rural area with a transfer warehouse, houses, and eventually out of town to a siding for unloading freight cars.

Thursday, March 31, 2011

Sunday, March 20, 2011

J&C Studios O-Scale Archive

Are you involved in the O-Scale Model Train hobby? Do you have a model railroad and would you like a place to publish your articles, how-to's, projects, or to showcase your work to share with others?

J&C Studios O-Scale Archive site is a collection of interesting articles, photo essays, tutorials, how-to's, stories, and showcases of the various O-Gauge train and model railroad layout projects members have embarked upon over the years. Feel free to explore these by starting at the main page: J&C Studios Archive

Registration and participation is totally free, and as a member you automatically get your own personal section where you can publish your own O-Scale related topics.

J&C Studios O-Scale Archive site is a collection of interesting articles, photo essays, tutorials, how-to's, stories, and showcases of the various O-Gauge train and model railroad layout projects members have embarked upon over the years. Feel free to explore these by starting at the main page: J&C Studios Archive

Registration and participation is totally free, and as a member you automatically get your own personal section where you can publish your own O-Scale related topics.

DCS down for a while, Legacy up

A few days ago the Track Interface Unit (TIU) for my MTH DCS system stopped putting out the DCS signal to Fixed 1 Output. As it worked one day and not the next and the DCS system is only about a month old, I am assuming marginal electronics from the initial build. I had to return it to MTH for warranty repair and was quoted 5 weeks turnaround! Yikes! (actual turnaound time was a little over 1 week)

Since these TIU's can be somewhat fragile and I don't want to be without running trains for over a month, I went on a mission to find myself a backup Rev. L DCS System. There is very limited stock on these nationwide, but an email blast out to many dealers I found on the MTH web site yielded me a new system the next day. In an effort to better protect the TIU from future issues, I installed 10-amp inline mini fuses on all my power drops from the transformers. I applied the latest firmware update from MTH regarding the AIU problem, and then updated to DCS 4.20. All is working fine at this time.

Also this week I ordered the Version 1.3 software update to my Lionel Legacy Remote system. The update was free from Lionel and was in my hands two days from my order. Also, I ordered a replacement LED headlamp harness for my 6250 switcher via the Lionel online parts ordering system and this worked great! Again, two days from order to my house without having to talk to a human. Lionel is doing much better than MTH as far as parts availability, repairs, and turnaround times.

If you missed it, I have decided to run my MTH DCS and Lionel TMCC/Legacy engines on electrically-separate blocks. This was fairly easy to do since my control panel was set up for block wiring and multiple power supplies from the start. This was all due to the DCS signal being severely degraded when TMCC engines were running on an electrically-connected track. The issue was not solved by installing 22uH chokes as suggested, and I decided to just separate them and get on with life.

All is working fine now, and I really haven't lost much, if any, functionality.

Since these TIU's can be somewhat fragile and I don't want to be without running trains for over a month, I went on a mission to find myself a backup Rev. L DCS System. There is very limited stock on these nationwide, but an email blast out to many dealers I found on the MTH web site yielded me a new system the next day. In an effort to better protect the TIU from future issues, I installed 10-amp inline mini fuses on all my power drops from the transformers. I applied the latest firmware update from MTH regarding the AIU problem, and then updated to DCS 4.20. All is working fine at this time.

Also this week I ordered the Version 1.3 software update to my Lionel Legacy Remote system. The update was free from Lionel and was in my hands two days from my order. Also, I ordered a replacement LED headlamp harness for my 6250 switcher via the Lionel online parts ordering system and this worked great! Again, two days from order to my house without having to talk to a human. Lionel is doing much better than MTH as far as parts availability, repairs, and turnaround times.

If you missed it, I have decided to run my MTH DCS and Lionel TMCC/Legacy engines on electrically-separate blocks. This was fairly easy to do since my control panel was set up for block wiring and multiple power supplies from the start. This was all due to the DCS signal being severely degraded when TMCC engines were running on an electrically-connected track. The issue was not solved by installing 22uH chokes as suggested, and I decided to just separate them and get on with life.

All is working fine now, and I really haven't lost much, if any, functionality.

The road less taken

This was my first attempt at making roads for my model railroad. After considerable research and a failed attempt or two, I found a system that works for me.

You will need the following supplies: 1/8" masonite or 1/8" foam core, Gesso canvas primer, heavy body acrylic paints in yellow and gray, 1/8" art tape (any color), 1/8" white auto pin striping, and foam brushes. Art stores like AC Moore have everything except masonite and pin striping.

I made one road using masonite as the base and others using black foam core. The masonite is obviously more rigid but causes more mess when cutting. Cut masonite with a circular saw and foam core with an Xacto knife. I went with 2½" driving lane widths and 2" parking space widths for my O-scale layout. My crosswalks were about 1" wide and my parking spaces were about 5" long each.

It is recommended to prepare and prime the surface using Gesso, a canvas primer which is similar to thick white paint and dries very quickly. If using foam core be sure to prime both sides or it will warp. Wait for the Gesso to dry completely.

Figure out where your yellow line and crosswalks will be and mark them lightly with a pencil on the primed base. For a double yellow line simply draw one light pencil line down the center of the road. Using the foam brush and yellow heavy body acrylic paint, paint a 1" to 1½" wide bar of yellow over the center pencil line. Wait until the yellow paint dries completely. This is very important because you will be applying art tape over the yellow paint in the next step and if it is not dry it will pull up the paint and ruin your line.

When the yellow paint is completely dry, run a piece of 1/8" art tape down the center of the road. Now run another 1/8" piece of art tape alongside the first one. Next run another piece of 1/8" art tape along the center piece on the other side of the road. Now carefully pull up the first piece of art tape you laid (the center one), leaving the other pieces of tape as a mask for your double yellow line. Unfortunately I do not have a photo of this step, but your project should look like the above photo with two pieces of art tape on the yellow paint masking your double yellow line.

Now carefully paint over the entire board including the yellow paint and art tape with the gray acrylic paint using a larger foam brush. Use lighter strokes to smooth the surface. Use just enough paint to get a complete coverage.

Wait for the gray paint to dry to the touch then carefully dig up the end of the art tape with an Xacto knife and peel back at an angle from the center slowly, revealing your yellow paint underneath. You should end up with something like this:

Mark your crosswalks and parking space lines very lightly with a pencil. Cover your pencil marks using the 1/8" white auto pinstripe. I left my pinstripes a little longer and wrap them around the edge and underneath the road base.

Here are a couple quick shots after I laid my road on my layout. I just tossed a couple cars and buildings in there to get an idea, but this is nowhere near being the complete project.

Overall, this was a pretty simple process once I figured it out. The acrylic paints are relatively expensive, but the paints go a long way and do not generate the fumes and overspray that spray paint does. Foam core is a bit expensive too, but cutting is much cleaner and easier than masonite with the end product much lighter and easier to locate.

You will need the following supplies: 1/8" masonite or 1/8" foam core, Gesso canvas primer, heavy body acrylic paints in yellow and gray, 1/8" art tape (any color), 1/8" white auto pin striping, and foam brushes. Art stores like AC Moore have everything except masonite and pin striping.

I made one road using masonite as the base and others using black foam core. The masonite is obviously more rigid but causes more mess when cutting. Cut masonite with a circular saw and foam core with an Xacto knife. I went with 2½" driving lane widths and 2" parking space widths for my O-scale layout. My crosswalks were about 1" wide and my parking spaces were about 5" long each.

It is recommended to prepare and prime the surface using Gesso, a canvas primer which is similar to thick white paint and dries very quickly. If using foam core be sure to prime both sides or it will warp. Wait for the Gesso to dry completely.

Figure out where your yellow line and crosswalks will be and mark them lightly with a pencil on the primed base. For a double yellow line simply draw one light pencil line down the center of the road. Using the foam brush and yellow heavy body acrylic paint, paint a 1" to 1½" wide bar of yellow over the center pencil line. Wait until the yellow paint dries completely. This is very important because you will be applying art tape over the yellow paint in the next step and if it is not dry it will pull up the paint and ruin your line.

When the yellow paint is completely dry, run a piece of 1/8" art tape down the center of the road. Now run another 1/8" piece of art tape alongside the first one. Next run another piece of 1/8" art tape along the center piece on the other side of the road. Now carefully pull up the first piece of art tape you laid (the center one), leaving the other pieces of tape as a mask for your double yellow line. Unfortunately I do not have a photo of this step, but your project should look like the above photo with two pieces of art tape on the yellow paint masking your double yellow line.

Now carefully paint over the entire board including the yellow paint and art tape with the gray acrylic paint using a larger foam brush. Use lighter strokes to smooth the surface. Use just enough paint to get a complete coverage.

Wait for the gray paint to dry to the touch then carefully dig up the end of the art tape with an Xacto knife and peel back at an angle from the center slowly, revealing your yellow paint underneath. You should end up with something like this:

Mark your crosswalks and parking space lines very lightly with a pencil. Cover your pencil marks using the 1/8" white auto pinstripe. I left my pinstripes a little longer and wrap them around the edge and underneath the road base.

Here are a couple quick shots after I laid my road on my layout. I just tossed a couple cars and buildings in there to get an idea, but this is nowhere near being the complete project.

Overall, this was a pretty simple process once I figured it out. The acrylic paints are relatively expensive, but the paints go a long way and do not generate the fumes and overspray that spray paint does. Foam core is a bit expensive too, but cutting is much cleaner and easier than masonite with the end product much lighter and easier to locate.

Thursday, March 17, 2011

K-Line Smoking Caboose - "Too much voltage, sir!"

A recent acquisition is a K-Line Burlington Northern Smoking Caboose. It is nicely detailed, has interior and exterior lighting, and a smoke unit. Not thinking much about it, I put it on my track and powered it up...in command mode...all 18 volts. The smoke unit smoked really well...REALLY well! And it kinda smelled like burn. Not good. I turned it off, put some more smoke fluid in, tried again. Same thing. Well this puts out way too much smoke, I said, so I flipped the switch on the bottom to turn the smoke unit off. It took a back burner.

Then someone recently posted on the OGR forum that the exact thing happened to him. Interesting. Long story short, these K-Line cabooses were made to run on more like 12 volts than 18 volts. A fellow forum member suggested installing some 3-amp diodes in-line on the hot wires on the 2 pickup rollers, orienting the diodes similarly in relation to the load (aka smoke unit and lights). These diodes would absorb or cut out the one phase of the AC current, effectively leaving 1/2 the voltage. I could apply 18 volts to the track but only 9 volts would make it to the internal electrical parts of the caboose. So I set out to do just that as an evening project.

I took the the shell off by taking 4 small phillips screws out of the bottom. The most difficult part of the whole job was dealing with the ladders on the end and the related walkways on the roof. The ladder tops go through the walkways and into the roof of the caboose, and the walkways are held to the roof by the tiniest screw-nails known to man. You will lose them. Why I didn't, I don't know. I attempted a photo of one sticking down through the walkway.

Once inside, I removed the shrink tubing and cut the hot wires from each pickup roller. I soldered in the 3a diodes in the same relative direction on each pickup wire as shown, far left and right.

I then taped up the connections with electrical tape and re-assembled...and put those tiny screw-nails back in place.

It works great! The fully-assembled photo shows it smoking, running off of 18v of track power with the diodes installed.

As all my electrical projects, I'm sure it wouldn't obtain a UL Listing, but mission accomplished anyway.

Total basement time: approx. 1 hour

Then someone recently posted on the OGR forum that the exact thing happened to him. Interesting. Long story short, these K-Line cabooses were made to run on more like 12 volts than 18 volts. A fellow forum member suggested installing some 3-amp diodes in-line on the hot wires on the 2 pickup rollers, orienting the diodes similarly in relation to the load (aka smoke unit and lights). These diodes would absorb or cut out the one phase of the AC current, effectively leaving 1/2 the voltage. I could apply 18 volts to the track but only 9 volts would make it to the internal electrical parts of the caboose. So I set out to do just that as an evening project.

I took the the shell off by taking 4 small phillips screws out of the bottom. The most difficult part of the whole job was dealing with the ladders on the end and the related walkways on the roof. The ladder tops go through the walkways and into the roof of the caboose, and the walkways are held to the roof by the tiniest screw-nails known to man. You will lose them. Why I didn't, I don't know. I attempted a photo of one sticking down through the walkway.

Once inside, I removed the shrink tubing and cut the hot wires from each pickup roller. I soldered in the 3a diodes in the same relative direction on each pickup wire as shown, far left and right.

I then taped up the connections with electrical tape and re-assembled...and put those tiny screw-nails back in place.

It works great! The fully-assembled photo shows it smoking, running off of 18v of track power with the diodes installed.

As all my electrical projects, I'm sure it wouldn't obtain a UL Listing, but mission accomplished anyway.

Total basement time: approx. 1 hour

Sunday, March 13, 2011

BNSF ES44AC Loco in the house!

In my previous blog post, I wrote about my bad experience with a Lionel Norfolk Southern Genset and was an unhappy Vision Line owner for all of a few hours. I returned the Genset and swapped it for the Burlington Northern Sante Fe ES44AC Diesel. This Lionel Legacy locomotive is essentially the same as the Vision Line GE Evo Hybrid, but seemingly a slightly newer production generation which hopefully irons out some of the problems with the Evo. This loco is not officially a Vision Line product, but the only thing it doesn't have are the chaser charging lights and it has plastic grills on the back of the shell instead of metal on the Vision Line. So I consider it my Vision Line loco.

I had the LHS open it on site to check for any obvious damage or rust. This thing is almost all die-cast and weighs in at about 15 lbs! The detail is incredible. As I watched the guy at the hobby shop unpack this loco, a thought occurred to me that may be part of the problem with these Vision Line products from Lionel. They may be "too detailed" and too fragile to be operating models. As he struggled slightly to grasp the loco while removing the overwrap plastic and packaging, I mentioned how I always grabbed locos by the trucks to avoid touching the shells and getting body oils on the paint. I asked him where you grab these new models because the trucks are so detailed and fragile that one would most certainly break something by lifting a 15 lb loco this way.

He showed me how he grabbed it in the general area of the front of the trucks near the steps. Let's pause here for this important note and repeat. He grabs them by the front of the trucks near the "steps". Fair enough I thought. We packed it up and I brought it home.

At home, I unpacked it very carefully and set it on the track. Before even powering it up, I did something I've never really done with a new loco before. I just stared at it for about 3 minutes, in awe of the detail and realism all the while looking for flaws and issues. As I inspected the couplers and played with the new concept semi-fixed pilot, I realized two things. The first was that when I pushed the pilot to the one side, the white handle on the coupler cut bar hit the yellow deck above. Further inspection of the yellow handrails on both the front and back of the loco revealed they were both bent during production or packaging. I carefully bent them into place without issue, and did the best I could to bend the coupler cut bar into a better position. I decided to invert the loco into my foam cradle to do an initial lube and inspection. This is where I found that 2 of the bottom steps on the pilot were broken off but still hanging, and another one was actually glued back on at the factory! So Lionel clearly knows these things are fragile as they appear to break them during their own production and packaging.

In the end, I had a choice to make. Since this particular unit ran flawlessly and the sounds, lights, couplers and smoke unit worked as expected, I decided to just glue the steps back on the best I could and live with it. You can't see anything when the loco is right side up, but until I learn a better way I will be lifting these locos from the fuel tank area. There are very limited places to grasp a very fragile 20" long 15 lb highly detailed model without damaging it. You can't grab the handrails, trucks, or pilots. The cab roof and rear roof come off, and as mentioned avoiding grabbing the shell in the middle is preferred.

If it continues to run as well as it does now, I am satisfied and have learned an important lesson about handling and packaging these things. I also stand behind my statement that Lionel needs to beef up quality control and build quality to keep these things from being damaged and/or defective out of the box.

I had the LHS open it on site to check for any obvious damage or rust. This thing is almost all die-cast and weighs in at about 15 lbs! The detail is incredible. As I watched the guy at the hobby shop unpack this loco, a thought occurred to me that may be part of the problem with these Vision Line products from Lionel. They may be "too detailed" and too fragile to be operating models. As he struggled slightly to grasp the loco while removing the overwrap plastic and packaging, I mentioned how I always grabbed locos by the trucks to avoid touching the shells and getting body oils on the paint. I asked him where you grab these new models because the trucks are so detailed and fragile that one would most certainly break something by lifting a 15 lb loco this way.

He showed me how he grabbed it in the general area of the front of the trucks near the steps. Let's pause here for this important note and repeat. He grabs them by the front of the trucks near the "steps". Fair enough I thought. We packed it up and I brought it home.

At home, I unpacked it very carefully and set it on the track. Before even powering it up, I did something I've never really done with a new loco before. I just stared at it for about 3 minutes, in awe of the detail and realism all the while looking for flaws and issues. As I inspected the couplers and played with the new concept semi-fixed pilot, I realized two things. The first was that when I pushed the pilot to the one side, the white handle on the coupler cut bar hit the yellow deck above. Further inspection of the yellow handrails on both the front and back of the loco revealed they were both bent during production or packaging. I carefully bent them into place without issue, and did the best I could to bend the coupler cut bar into a better position. I decided to invert the loco into my foam cradle to do an initial lube and inspection. This is where I found that 2 of the bottom steps on the pilot were broken off but still hanging, and another one was actually glued back on at the factory! So Lionel clearly knows these things are fragile as they appear to break them during their own production and packaging.

In the end, I had a choice to make. Since this particular unit ran flawlessly and the sounds, lights, couplers and smoke unit worked as expected, I decided to just glue the steps back on the best I could and live with it. You can't see anything when the loco is right side up, but until I learn a better way I will be lifting these locos from the fuel tank area. There are very limited places to grasp a very fragile 20" long 15 lb highly detailed model without damaging it. You can't grab the handrails, trucks, or pilots. The cab roof and rear roof come off, and as mentioned avoiding grabbing the shell in the middle is preferred.

If it continues to run as well as it does now, I am satisfied and have learned an important lesson about handling and packaging these things. I also stand behind my statement that Lionel needs to beef up quality control and build quality to keep these things from being damaged and/or defective out of the box.

Saturday, March 12, 2011

Lionel Vision Line "blind" to quality control?

After hearing about how detailed and awesome the Lionel Vision Line Genset Switchers were, and consequently discounting all the noise I've heard on the train forum about problems with this unit, I decided to take the plunge and get the Norfolk Southern Genset from my LHS. I was excited because this would be my first Vision Line purchase and I wanted to see what all the hubbub was about. I read the manual, unpackaged it, put it on the track, and powered it up. The excitement and fun lasted a total of about 1 minute.

The engine had many issues that were unacceptable to me, most of which were detailed in the OGR forum by other owners. The main problem was that the third smoke unit didn't smoke…the fan ran, but no smoke came out. Then the smoke exhaust caps stuck open, and then stuck closed. The stuck caps caused the blowing smoke vapor to condense into a liquid and collect around the exhaust pipes. When the engine sat on the track after shutdown, it emitted a very loud hum through the speaker. The hinged panel on the side that hid the switches for changing setting was bent and crooked, and the label inside it for switch identification was upside down. The hatch on top behind the cab didn't lay flat. The unit was very limited in sounds as well. In general, it was a disappointment and a let down. And the horse on the logo is backwards! :) Ok, we all know that by now, by I just had to add that because Lionel will allow you to get a refund on the unit based solely on this problem.

On the positive side, it is a beautiful engine, well detailed, and ran what I think was 1 scale mph or less very consistently and smoothly due to its low gearing.

Sure, if I really would have liked it, I could have swapped it for another unit at the LHS or had it sent back to Lionel for repair. But I couldn't get over that being the "Vision Line" this was supposed to be the Cadillac of trains and for the money it cost, it shouldn't have any let alone all of these issues. It didn't make me feel good about owning it.

I ended up returning it and getting the BNSF ES44AC. More on that in the next post.

One good thing came of this though. I initially bought the Genset so I could finally upgrade to and experience the Lionel Legacy Control System. Setup was minimal with a slight learning curve, but in all I'm pretty impressed with the Legacy system. It is new to me and there are a couple things that need ironed out, but nothing critical I know of yet. It does make my TMCC locos run much slower and smoother with more speed steps. I registered it on the Lionel web site and am waiting for my v1.3 software upgrade.

I now have both Lionel Legacy and MTH DCS remote systems. Due to yet more issues, I have decided the best thing to do is to run these two remote systems on electrically separated blocks of track. But that story is a whole blog post in itself!

Monday, March 7, 2011

Lionel TMCC Engines interfere with MTH DCS signal quality

My Lionel TMCC engines kill my MTH DCS signal quality when they are running. It has been known for some time that the constant voltage lighting boards in the TMCC engines create interference with the DCS signal, and it is suggested to install a 22 uH 5.5-amp choke in-line on the hot lead from the TMCC pickup roller. I did this to the PostWar Celebration Series Seaboard 6250 Switcher with no luck. I also tried installing on the ground in-line per suggestion and still no go. No one seems to have any input as to what is going on, and I am thinking it might be the sparking of the pickup rollers from the TMCC engine while running since sitting idle does not cause any issues. Of course another solution is to dump all the Lionel engines and go all MTH...but that's for another day.

In the photo you can see the choke (the big black barrel on top) in-line on the ground lead, as well as one tucked in on the right on the hot lead (2-red wires coming from it). They do nothing to help my problem.

In the photo you can see the choke (the big black barrel on top) in-line on the ground lead, as well as one tucked in on the right on the hot lead (2-red wires coming from it). They do nothing to help my problem.

MTH Premier Montana Rail Link SD45 Low Hood Diesel

20-amp dedicated circuit for trains installed

I thought for a few days on how I was going to hook my surface mount boxes and conduit to the round lally column (post) in my basement. Tap the pole and screw to it? Shoot nails into it? JB Weld? Nothing sounded right.

Then it hit me! A large hose clamp for a dryer vent should work fine.

Home Depot to the rescue. Project complete.

Then it hit me! A large hose clamp for a dryer vent should work fine.

Home Depot to the rescue. Project complete.

DCS Remote - Limited LCD Contrast with Rev. L

The handheld remote control (in the late 2010/early 2011 shipments of DCS Systems with Rev. L TIU) has limited contrast. The fix involves moving the resistor from pin 7 to pin 6 on the leg of IC U161. After moving the resistor to the correct position the LCD now appears to have its normal range of contrast. You will need a very small tip soldering iron, a magnifier, nerves of steel, and some luck to pull this off. I repaired mine but wouldn't want to do it repeatedly without better tools. The photo shows the correct location of the resistor.

Subscribe to:

Posts (Atom)